Cold Rolling

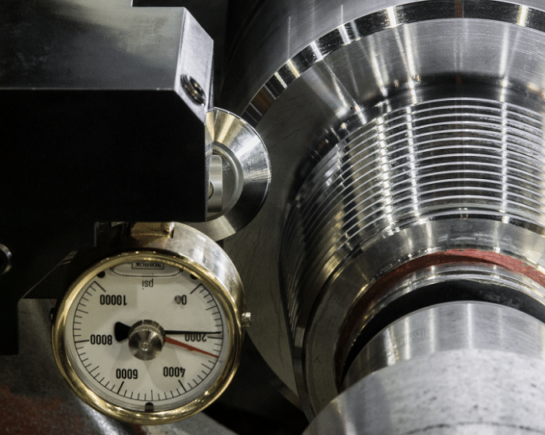

Cold Rolling is the process of burnishing the root radius of a previously cut thread in a Rotary Shouldered Connection or thread profile. A hardened roll, similar in profile to the thread being manufactured, is placed in contact with the root radius of the tapered thread, and pressure is applied to force the roller to penetrate into the cut surface of the root radius, displacing and cold-forming the thread material.

This deformation cold-works the material, imparting an improved surface finish and compacts and displaces the grains of the root material.

Industry experience with the Cold Rolling process has suggested an increase in fatigue life of 3 to 5 times over similar un-treated connections under the same working environment. Some studies have noted laboratory results of up to 27 times better life attributable directly to cold root rolling process.

Kampen Machinefabriek have offered this service for many years and it is In fact an obligatory process when operating to the NS-2 standard among others.

Request a quote by completing the next form.

One of our experts will contact you shortly and give you the right informations and quotation you need.