Thread Repair & Rework

A damaged thread on tooling can be frustrating in the field. Luckily repairing API and other tapered threads is a straightforward process.

Kampen Machinefabriek Velsen has been repairing customers’ damaged rotary tool threads for over 30 years.

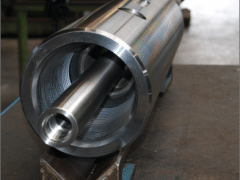

We can repair all standard API threads as well as a full range of other less common threads (eg Full Hole, Internal Flush etc). We can cut completely new threads, or to perform thread re-works.

Thread Re-works are possible when the damage to the thread is not too great (but enough to cause the tool to fail inspection).

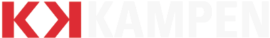

Our large bed lathes

Our large bed lathes allow us to repair the threads on tools of up to 26” OD. We also have pipe stands attached to our larger lathes which allow us to easily repair full length Range II tooling (31’ / 9.5m).An example list of some of the tapered threads we repair is below:

- 2 3/8 Reg, 2 7/8 Reg, 3 ½ Reg, 4 ½ Reg, 6 5/8 Reg, 7 5/8 Reg,

- 2 3/8 IF, 2 7/8 IF, 3 ½ IF, 4 IF, 4 ½ IF, 6 5/8 IF, 7 5/8 IF

- 5 ½ FH (DS),6 5/8 FH (DS)

CNC and traditional lathes

We perform thread repairs using both our CNC and traditional lathes. While CNC lathes are great for new thread re-cuts, our traditional lathes are well suited for thread re-works.

When making a new thread, the old thread is completely removed and a new one is recut. In comparison, by re-working a thread, only a small amount of the original thread is removed. This conserves the overall length of the tool as much as possible thus increasing the overall lifetime of the tool. It is also a more economical process overall.

Request a quote by completing the next form.

One of our experts will contact you shortly and give you the right informations and quotation you need.